L-I Battery Fires in Scrap Yards: Mitigating Risk, Contamination

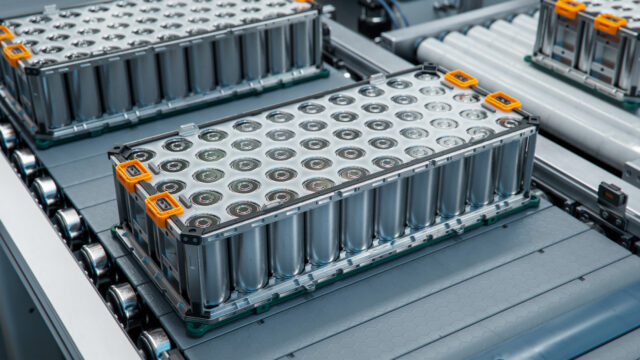

Lithium-ion battery component for an electric vehicle.

Lithium Ion (L-I) batteries now exist in many items we all use, from mobile devices to e-scooters, bikes, and electric vehicles. The main concern with L-I batteries is fire risk, with residences, vehicles and businesses catching fire.

When L-I batteries enter waste streams and remain undetected, they can cause huge fires at landfills and recycling plants — putting yard personnel and the surrounding community at risk due to the release of toxic gasses from the batteries.

The challenge is that most consumers “are not aware of the safety, fire, and insurance risks posed by improperly manufactured, charged, stored, damaged or discarded rechargeable batteries and battery-containing devices, particularly lithium-ion batteries,” ReMA stated in its February 27, 2025 position paper, ReMA Position on Non-Embedded Small and Medium Format End-of-Life Battery Management.

L-I battery fires behave differently and require different suppression methods. The problem isn’t the fire per se — it’s the chemical release. Randy Narine, an active fire fighter, and CEO of Clean Core Research, shared his insights in an interview with Recycling Product News (source).

“This is the biggest education point that I’m trying to get out there,” says Narine. “The fire is one piece. The structure collapse is another. The biggest concern for me is the actual chemical release; identifying what’s been exposed, cleaning it up, and mitigating that risk.”

His concern extends well beyond scrap yards. A CBS News report about L-I fires interviewed a homeowner who lost his house to a L-I fire — the battery was in the vacuum cleaner, which had been left on the charger too long. His children, who were alone in the house, safely escaped; his two cats did not.

In another incident, a mobile phone caught fire on a plane mid-flight, filling the cabin with smoke. L-I fires burn hotter and spew toxins. In the video, you can see people on the flight holding tissues to their noses in order to breathe.

The toxic chemicals can contaminate anything they come into contact with, such as the wiring and electronics critical to the aircraft’s function.

Narine’s Toronto, Canada company conducted an investigation following a lithium battery fire in a residential setting. Although the fire was extinguished quickly, within days the home began showing signs of corrosion, including degraded outlets, rusted tools, and the HVAC system testing positive for chemical contamination.

This same kind of hidden damage, Narine says, “can occur in scrapyards and MRFs. The byproducts create some serious oxidation. It will rust metal at an astronomical rate.”

Scrapyard owners: Take proactive steps

The first step is risk assessment. As ReMA states in its position paper, an L-I battery in your scrap pile isn’t a what-if; it’s a given. If a fire were to start in your yard, who or what is at risk? While the safety of workers is your primary concern, what critical infrastructure could be damaged due to contamination or oxidation?

Narine recommends developing and adhering to proper handling and storage of L-I batteries to prevent unintentional fires that could shut you down.

Second, make a plan. Consult with your local fire officials to understand their approach to L-I fires and hazardous gas containment versus simply extinguishing the fire. If a fire were to occur, ensure you have a plan for safe evacuation of all yard personnel and quickly notifying first responders.

Your plan should also include post-fire testing, clean up, long-term response. The huge problem with L-I fires is the long-term contamination to surrounding structures and equipment, the soil, and even the PPE worn by yard personnel.

Keep abreast of state and Federal regulations and updates regarding L-I batteries

According to ReMA, states are considering end-of-life battery management legislation for small, medium, and large format batteries, and battery-embedded devices.

At the end of 2024, New Hampshire’s then Governor Sununu signed legislation, to take effect July 2025, that bans lithium-ion batteries and some electronic waste from disposal at New Hampshire landfills and incinerators, stemming a serious fire hazard. (source)

The key, however, is public awareness and education. While NH’s new law “requires owners and operators of disposal facilities to take steps to prevent the disposal of the batteries and electronics,” preventing disposal in the first place is difficult — especially since recycling opportunities are still difficult to locate in many states.