Andrew Halonen of Mayflower Consulting presented at the AFS Metalcasting Congress 2021 about the trends of reducing weight in metalcastings (aka “lightweighting”).

This topic is of interest to the metal recycling industry in particular. As vehicle designers work to reduce weight in order to meet federal and state fuel economy guidelines – as well as reduce vehicle manufacturing costs – fewer ferrous casted parts will be needed.

Although more manufacturers are incorporating lightweighting into their designs, the changeover is still met with some resistance. Halonen cited four reasons: Cost, system over component, changing the supply chain, and other material innovations.

Once a manufacturer decides to change the material makeup of a part – for example, moving from aluminum to an aluminum alloy or other material – the manufacturer is forced to seek out new suppliers. Vetting new suppliers and their facilities and processes is costly and time-consuming.

And, while a manufacturer may redesign one part to be lighter, other parts are redesigned to incorporate more steel or iron depending on load, wear, function, etc. – negating the overall weight savings.

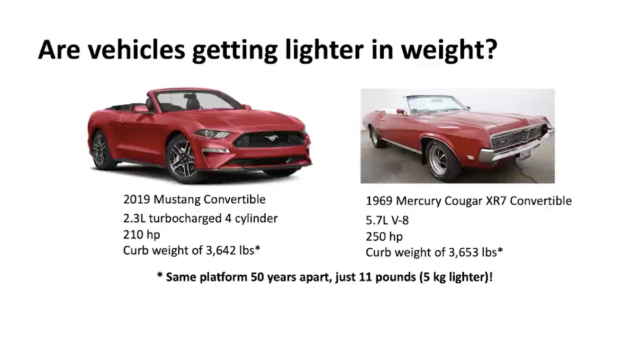

In one example, Halonen compared the 2019 Mustang Convertible with the 1969 Mercury Cougar XR7 Convertible. Both vehicles feature the same platform – yet in 50 years, only 11 pounds have been shaved off the weight!

© Andrew Halonen, Mayflower Consulting

Trends in EVs

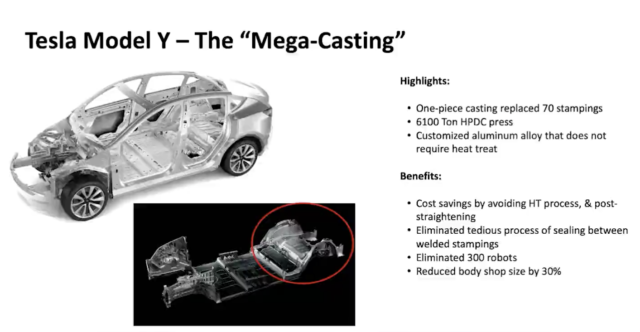

For the Tesla Model Y, the company is now using a one-piece casting (referred to as the “skateboard” chassis), which has replaced 70 castings. The chassis is a customized aluminum that doesn’t require heat treat.

© Andrew Halonen, Mayflower Consulting

EV manufactures are also using bi-metal construction of parts – for example, aluminum and steel. The steel is incorporated into the load-bearing area of the part.

Interestingly, Tesla and other manufacturers are incorporating more steel and less aluminum to make EVs more affordable.

Impact to metal recyclers and auto shredder yards

Lightweighting changes will have some impact to metal scrap and vehicle recyclers. For scrap recyclers with shredding capabilities, more specialized tools and knowledge may be needed to dismantle and shred EVs.

Auto dismantlers will want the larger aluminum castings and the more valuable motors, chips, and computers, as well as the lightweight alloy castings and expensive plastic components. All of this means less material for scrap recyclers.

Vehicle recyclers will also need to consider the environmental impact and additional costs of de-manufacturing EV vehicles – especially the batteries, fuel cells and other non-recyclable components that will require remediation.

Shredding equipment, however, won’t need to change much. Shredder yards will miss the non-ferrous metals traditionally found in vehicles as lightweighting gains traction. But, this has been the trend anyway, so most scrap recyclers are ready.

Advances in non-ferrous recovery are helping scrap recyclers keep pace with the loss of automotive non-ferrous by recovering more from the other components of shredder feedstock.

For additional insight about lightweighting and industry examples, download Andrew Halonen’s piece “Trends in Lightweighting with Metal Castings” featured in the May/June 2020 issue of Casting Source (link goes to PDF at Halonen’s website).