Infrared Camera Positions for Shredder Infeed

Why use an infrared (IR) camera at your shredder infeed? They do pay for themselves in short order with more tons per hour and less delay time over the course of a shift. And there are ways to keep them out of harm’s way.

Damp and wet system shredders produce a fair amount of steam to accomplish their goals for dust control and regulating the mill box environment. Get the dew point close to the air temp and you have a lot of steam, really obscuring the view of the feed chute.

One solution is the infrared camera to peer through the steam. The heat from the shredder lights up the view from behind, creating a back lighted view of what’s in front of the heat. That would be your feed stock in the feed chute.

While you don’t have to see what’s in front of the DFR, it is extremely helpful to avoid jams and underfeed minutes to the mill. Keeping the feeder rolling and the mill box full is what it’s all about. Pencil in the total minutes of non productive time with feed issues against the cost of the camera system, and you will find the cost of a camera reasonable.

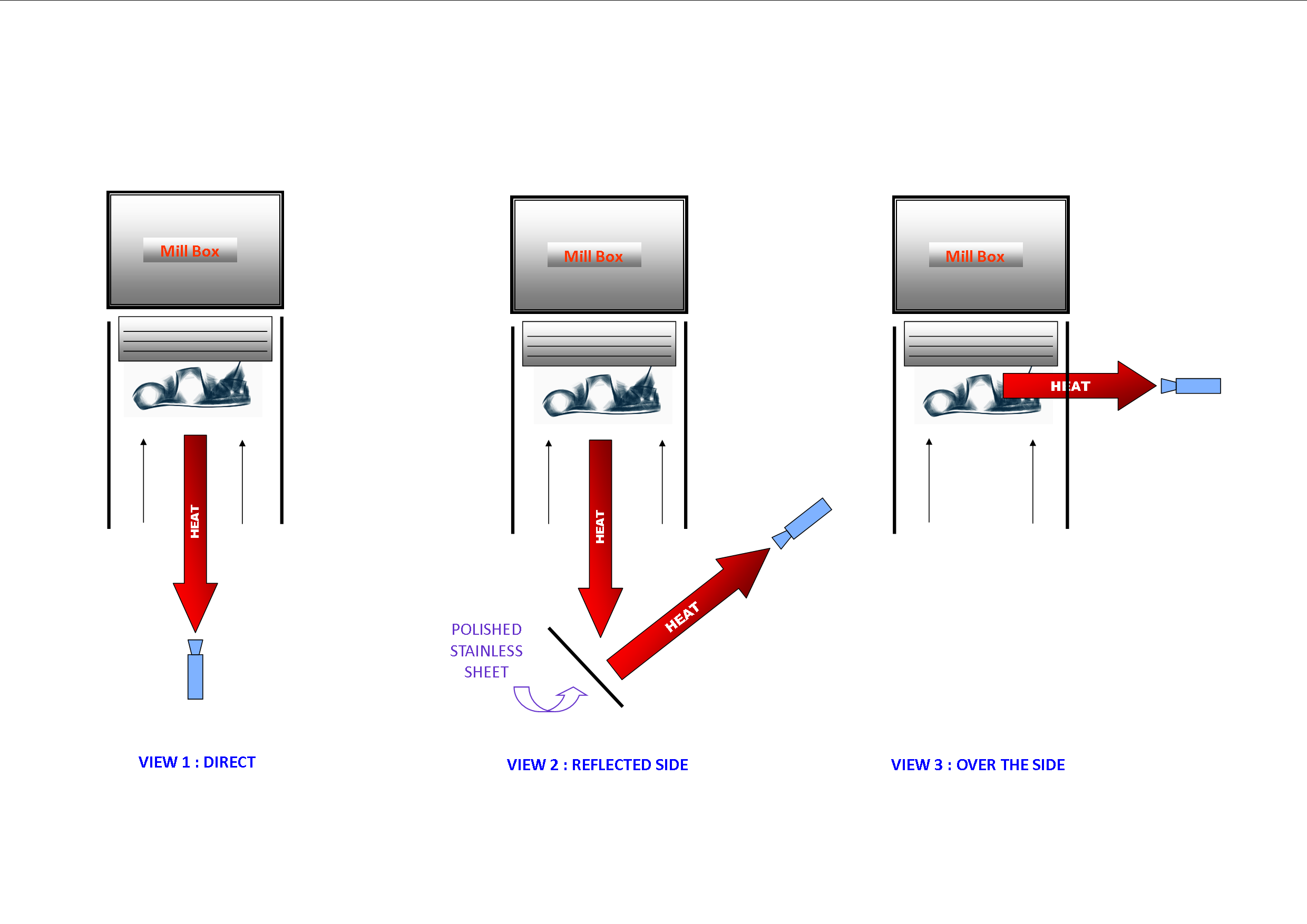

A direct camera alignment takes in a full heat signature and gives the best camera image. But the direct mount is also subject to direct damage. Fortunately new camera’s are more sensitive and allow for some alternate mounting methods.

View 1 is the direct mount, with full heat ‘lighting up’ the scrap in front of it. Bright and sharp views, but hard to maintain and service.

View 2 is the reflected side mount. The heat signature can be bounced off a polished reflective surface and seen by the camera safely mounted to the side. A stainless sheet with adjustable mount works well. We’ve heard of commercial flat screen TV brackets working well to adjust the reflector. The camera is out of harm’s way, but you need a high enough mounting point for the reflector to keep it clear of the scrap moving over the infeed conveyor.

IR Camera Positions

View 3 is a side mounted camera. New IR systems are sensitive enough to present the scrap profile in front of the feed rollers even from a side view. The camera is very much out of harm’s way, but you need a tall mount to look over the side of the feed chute.

The side mount is often the easiest mount, close to platform or protective screen, with less cable run, and easy access. How does it look? See the video below. This camera is a FLIR model A300 with 17mm lens provided as a package by Shredder Vision.

many potential positions, in the majority of applications it is best in terms of performance and reduced wear parts cost, to use fewer

many potential positions, in the majority of applications it is best in terms of performance and reduced wear parts cost, to use fewer