What’s Needed to Replace Your Shredder Rotor?

Your wear parts have been doing a great job for many tons of production. After several years, it’s time to replace your shredder rotor. What are your options and what exactly do you need to plan the job? How do you start finding a replacement? Here’s some information and explanation to get you started.

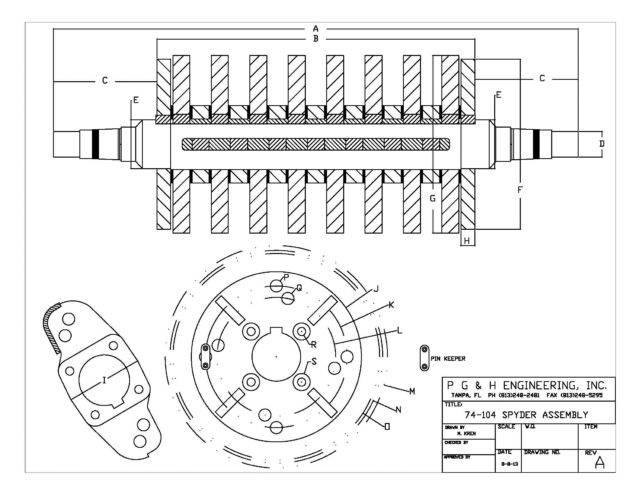

Find your rotor arrangement drawing. The drawing shows the entire rotor and describes its major dimensions, weight, shaft size and general assembly. With this drawing, a rotor builder understands the style and quantities needed to build a rotor.

They can estimate materials and general time needed, enabling them to provide you a quote. You need to describe what it is you are buying. A picture is worth a thousand words. Here is a rotor template drawing from PG&H if you need to make your own.

Describe your hammer and hammer pin size. A drawing with some basic dimensions is ideal. If you don’t have one, go to our quote page and download the hammer template you need (such as bell hammer) and use it to describe your hammer. The rotor builder needs to confirm your hammer swing radius, thickness, and pin hole size. Provide them hammer pin diameter and length. We have a template for hammer pins as well.

Get with your operating crew and determine the specific needs at the shredder. Yes, you need a new rotor, but what else? Here are the common replacement items for a rotor change out.

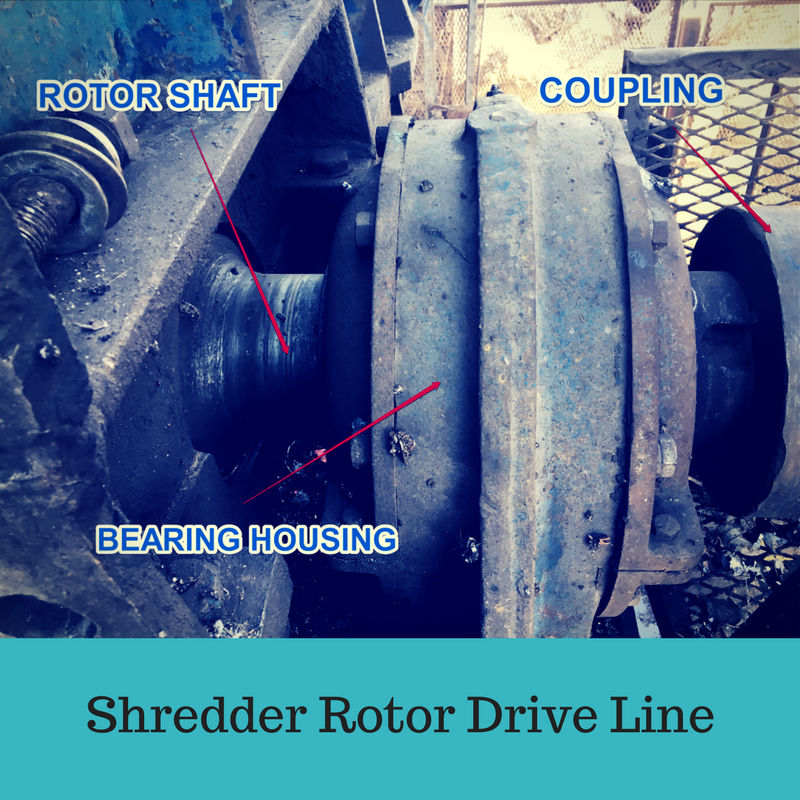

Bearing housings

These hold the bearings and attach the rotor shaft to the shredder. They get worn and damaged as well. If in good shape they can be renewed.

These hold the bearings and attach the rotor shaft to the shredder. They get worn and damaged as well. If in good shape they can be renewed.

You should have a spare set on hand and can plan to use them. If they have yet to be renewed, get them cleaned up and sent out to a shop that can build them up and machine them to restore a secure fit.

Oil seals

Seals keep the lubricant inside the bearings housings. They are long lasting, but always replace with new during a bearing change.

Rotor bearings

Generally spherical tapered roller bearings are used. You should have a spare set on hand. If you need a fresh set, order early as lead times can vary by many weeks. Be sure your spare set is well stored and free of minor rust and dirt. Larger machines have oil cooled bearings, smaller mills may use greased bearings (not needing an oil re-circ system).

Coupling device

A means to connect the drive shaft to the rotor. You may be able to remove the old one and reuse it, use a spare, or plan on having a new one made by your rotor shop.

Drive Shaft

You will have the rotor out, so it’s the right time to service your drive shaft. Plan for it.

Bearing Base Plates and Shim Kit

The saddle is the mounting area on the shredder base where the bearing housing sits to anchor the rotor to the shredder itself. These surfaces are subject to wear themselves. The bearing housings should wear first, but in reality, both wear. The saddles will have to be cleaned and ground flat. The bottoms of the bearing housings will be milled flat in the shop. A steel base plate is used when you need to make of the difference in height from the wear of these two surfaces. A shim kit is useful for rotor alignment. It is a set of pre-cut metal shims to help you adjust rotor height when aligning the rotor drive train.

Thermocouples and Instrument Wiring

Oil cooled bearing generally have a temperature monitoring probe on the bearing oil. Often the probes and wiring will be damaged after years of shredder service. If they need to be replaced, plan for it now.

Bearing oil piping, hoses, fittings

Similarly, your bearing oil delivery system takes abuse over the years. You may need to replace piping or use fresh hose. You might want to get the bearing oil pump & reservoir cleaned and serviced during the rotor change as well.

Bearing bolts

The studs or bolts that hold down the bearings to the saddle base should generally be replaced. Bolts are made to have a certain amount of stretch. Once they have stretched and done their job, they don’t stretch and hold quite the same the next go around. Its a finer point and often, the bolts or studs are often reused. It’s best if you change them. Often the threads and nuts get damaged, so a fresh fastening system is good. After spending so much to replace the rotor, you’re are going to cut corners elsewhere in the installation? Just saying.

You have your shopping list. Go find yourself a rotor and replacement supplies. Call you your Original Equipment Manufacturer or one of the replacement builders out there, such as PG&H Engineering. Contact us if you need some advice.

many potential positions, in the majority of applications it is best in terms of performance and reduced wear parts cost, to use fewer

many potential positions, in the majority of applications it is best in terms of performance and reduced wear parts cost, to use fewer