Shrink Fit Coupling Removal

High torque drive couplings usually involve a shrink fit. The coupling is machined with a smaller diameter than the mating shaft. The coupling is heated 300-400 degrees hotter, expands and can be slipped onto the drive shaft. It cools, shrinks in diameter, and a tight mechanical fit is accomplished (with keyways or splines as well).

You may have to remove a shrink fit coupling when changing out drive motors or rotors. Your manufacturer’s rep can get you some advice on the pulling force and strength needed for a successful removal. Without adequate set up, you’ll bend or snap rods, and be left with hours of time to shed enough heat before you can work on the unit again for another attempt.

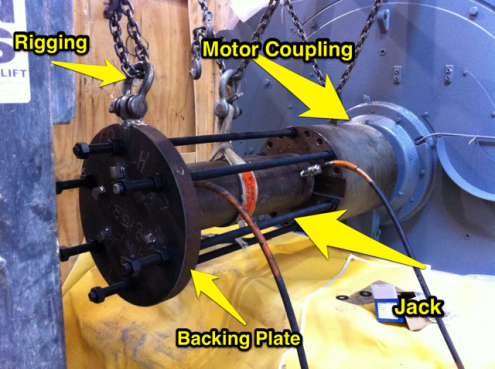

- You’ll need a lifting device and rigging to hold up several hundred pounds of coupling as you slide it off the shaft.

- 6 to 8 full diameter threaded rods seated full depth in your coupling’s end holes, and a few dozen nuts. Use grade 8 rod (150 ksi tensile) to give you full strength and minimal elongation.

- 2 inch thick backing plate

- 12-20 tons of jacking force. Hydraulic jack (s) and enough jack stroke to pull off the coupling. This may require a stub shaft insert if you the jack stroke is less than the coupling length.

- Torches and heating tips. Rosebud heating tips of proper size (8 or 10) are important. Using both propane and oxy acetylene torches is wise. Acetylene burns hotter and there is limited space to apply torches to the coupling. Make sure you have enough gases on hand in case you need more than one attempt to remove the coupling.

- Fire retardant blankets

- A clean and clear work area

- Fire fighting gear, a clear work area, and heat resistant PPE for personnel

- Your safety program may require a hot work permit

The key item is to heat the coupling quickly, so it expands before the shaft it’s mounted on heats up and expands as well. The difference in temps for allows for expansion. Also, excessive heat in the shaft can lead to damage of bearings, seals, and other components.

Always let things air cool. Never cool with water or gases like a CO2 fire extinguishers. If you have a fire emergency, do what you need to do to minimize loss of property or life. However quenching with water or anything else would likely damage the coupling or shaft steel.