Used Scrap Metal Ferrous Shredding System for Sale

An effective energy efficient metal shredding line up

Update: This unit has been sold

5000 HP Ferrous Scrap Metal Shredding System for sale. The heavy duty shredder box is 88 x 101 inch with 4 inch thick walls. This is a complete package with infeed conveyor, ferrous line, motors, pumps, water injection, and coolers. Many extras such as power systems and a computer managed over sized double feed roll allow this machine to shred serious volume in a compact package. 150 tons per hour ferrous out production.

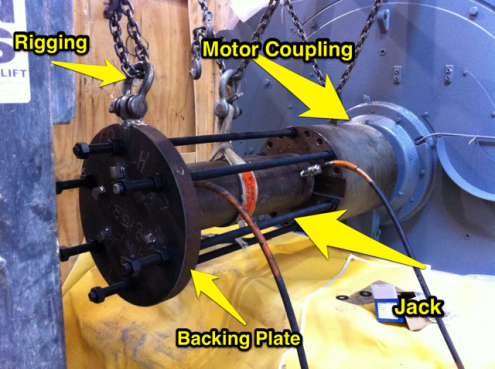

The primary drive is a 5000 HP (3730 KW) A/C Wound Rotor Motor. The hard charging Schorch motor keeps churning day after day. Dual axial pole magnets, cyclone air cleaning system, and split picking station allow for extremely clean and dense ferrous scrap.

Slip Power Recovery Drive is included. Motor rotor current is managed in a switchable duel system using either liquid rheostat or solid state SPR drive. The SPR efficiently runs the motor with greater power, cooler temperatures, more tons per hour, while allowing less flicker and inference with local electrical grid, thus greater options for relocating the installation. Comes with heavy duty GE transformer (25kV/4160), power factor capacitors, and many extras that take the added cost out of relocating the machine.

The system includes infeed conveyor, shredder dampening springs, under mill oscillator, conveyors, magnets, water injection system, de-dusting air cleaning zee box, dual picking station, stacking conveyor, and non-ferrous radial stacking conveyor. Many spare casting wear parts and spare parts are available. The motor room is protected by an air filtration system. Roof mounted coolers, control cabin, infra red camera, and shredder management computer round out the system. Non-ferrous separation system as NOT part of this package.

An effective and energy efficient equipment line up. A very complete system, well cared for with low tons on the machine. This unit represent an excellent opportunity for a new installation or if you are looking to replace an aging shredding plant.

Spare motor and rotor available as extras.

Contact us at k2.castings.com for more details. Serious inquires only.