Global manufacturers have set ambitious targets for using recycled materials to meet sustainability goals. According to Boston Consulting Group, Coca-Cola wants to use 50% recycled material in its packaging by 2030; General Motors wants to increase its share of sustainable materials to 50% or more this decade. (Source)

For a company like Coca-Cola, using recycled aluminum for its beverage cans makes sense: the material requires about 5% of the energy needed to produce new aluminum, plus aluminum can be recycled infinitely.

Nespresso is another company using recycled aluminum to meet sustainability goals.

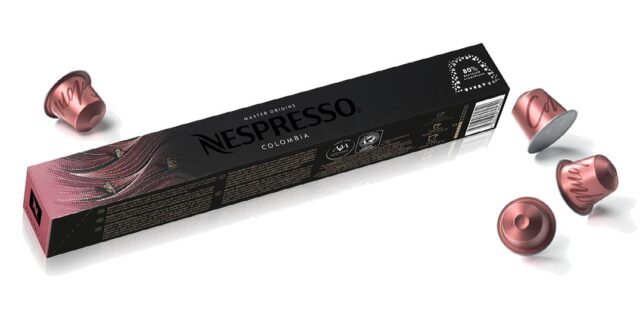

Nespresso Coffee Capsules: 80% recycled aluminum

© Nespresso

Nespresso, a B-Corp owned by Nestlé, has always focused on reducing waste and reusing product materials.

In 1991, the company created a recycling program that allowed its customers to return used coffee capsules – either to a Nespresso store or by mailing them in – versus tossing them in the trash. (In fact, the current coffee machines have mechanisms that eject the used capsules into a built-in holding container.)

In 2020, Nespresso announced the launch of its first coffee capsules made using 80% aluminum. Today, the entire coffee line incorporates recycled aluminum, and the company’s recycling efforts include 100,000 collection points worldwide for the capsules.

In addition, the company is the co-founder of the Aluminum Stewardship Initiative, which is focused on the “responsible production, sourcing, and stewardship in the global aluminum value chain.” (Source)

To learn more about the company and its environmental commitment, visit: https://nestle-nespresso.com

Made Trade – Sourcing Recycled Copper Cookware and Home Décor

Recycled Copper Cookware © Made Trade

As with aluminum, copper requires less energy to recycle and is also infinitely recyclable. Because of its high electrical conductivity, the material is mainly used in industrial applications: electrical / conductivity and communications, power generation and transmission, electrical circuitry and appliances, and building applications, such as plumbing / HVAC.

Trivia: When NASA launched its first manned rockets, the launch pads were located 400 feet from the cement-built block houses. Why 400 feet? At the time, that was the length of conductivity for the copper wire, which ran from the launch pad to the huge computer machines in the block house.

It’s estimated that of the 690 million tons of copper recycled in the last 100 years, two-thirds, or 460 million tons are still in productive use! (Source)

Less than 10% of copper available worldwide is used for consumer applications, such as cookware, jewelry, coins, and other items.

Founded in 2018, Made Trade is a small, family-owned business that sources ethically and sustainably-made home décor products. Each product is rigorously assessed and verified – and adheres to at least two of eight core values.

Made Trade carries a full line of recycled copper products, including cookware, platters and trays, and drinkware sets – each product handmade by artisans worldwide.

To view the recycled copper product line, visit: https://www.madetrade.com/collections/shop

Apple: Incorporating recycled aluminum and copper into devices

Did you know a new robot created by Apple can disassemble up to 1.2 million iPhones a year? Called Daisy, the innovative machine helps Apple recover more materials for reuse, including aluminum, gold, and tungsten – as well as the cobalt – found in iPhone batteries.

In April 2022, Apple announced its newest recycling innovation, Taz, “a machine that uses a groundbreaking approach to improve material recovery from traditional electronics recycling.”

A pilot-scale industrial shredder, Taz was designed to help conventional bulk electronics recyclers recover more precious rare earth metals.

At the Material Recovery Lab in Austin, Texas, engineers and experts use a pilot-scale industrial electronics shredder for research and development. Apple’s newest recycling machine, Taz, was developed out of this process, designed to help conventional bulk electronics recyclers recover more precious materials. © Apple

The recycling robots help not only extract materials for reuse, they also reduce the amount needed from mining – including copper:

From just one metric ton of iPhone components taken apart by Apple’s recycling robots, recyclers can recover the amount of gold and copper companies would typically extract from 2,000 metric tons of mined rock.

Apple also reports that in 2021, 59% of all aluminum used in its devices comes from recycled sources. The MacBook Air with M1 chip, released in 2020, now features 44% recycled content, including 100% recycled aluminum in its enclosure.

Read the full story at Apple’s website; you can also download their 2022 Environmental Progress Report.

Implications for metal recyclers: Cleaner product needed

Consumer manufacturers aren’t the only companies with sustainability goals. SDI La Farga Copperworks, based in New Haven, Indiana, has based its business model on sustainability.

A joint venture between Steel Dynamics Inc., Fort Wayne, IN and Barcelona, Spain-based La Farga Group, the copper producer incorporates a unique process for producing its InfinityTM copper.

Using reclaimed copper to lower environmental impact, the company produces Cu-FRHC (fire-refined, high conductivity) copper products that are 99.9% pure and meet ASTM B-49 standards.

The impact: Metal producers such as La Farga Copperworks will need significantly more recycled material that’s also clean. The challenge, however, is extracting material when it’s mixed with other metals.

According to the Boston Consulting Group piece cited above, recycling yards “are incentivized to focus on higher-value [aluminum] items and ignore aluminum content that’s mixed in with other materials. Mixed metals are harder to extract and they take more time.” Hence, material gets sent to landfills.

One solution shredder yards can incorporate: Water-based sink/float systems to target copper fines in the non-ferrous residue stream.

K2’s new line of recycling stars © K2 Castings

Systems that employ new separations for fluff, such as roll screens and water-based density separations, help target the heavier streams where copper and red metals reside. (See our post: Trends in Ferrous Recovery: Roll Screens).

Non-ferrous stream wire recovery and granulation are new forms of copper recovery being successfully integrated in shredder down streams. For example, Energy Creates Energy (ECE) delivers one such granulating system.

Instead of sending material overseas for processing, or to landfills, U.S. smelters can fabricate steel, aluminum, and copper for use in industrial and consumer products – keeping recycling local and prices and supply relatively stable while helping manufacturers meet sustainability goals.