From food products touting “made with 100% renewable energy” to clothing items made from recycled plastic, consumer products manufacturers now proudly proclaim their stewardship of the environment via their sustainable manufacturing processes.

Vermont Coffee: Roasted with 100% renewable energy

Environmental sustainability isn’t new: recycling scrap metal is the forerunner of the current movement. And today, metal recyclers are just as “earth friendly,” with processes that use less energy and generate fewer pollutants.

Recycled material is vital to our supply chain. U.S. steelmakers, for example, rely on recycled iron and steel to produce new steel. In 2019, U.S. steel mills consumed more than 60 million metric tons of the recycled material to produce 87 metric tons of steel. (Source: ISRI)

Producing new material from recycled scrap provides many environmental benefits: Using recycled material requires 60% less energy and reduces CO2 emissions by 58% when compared to producing steel from virgin materials. (Source: ditto)

When you think of steel, however, you generally picture steel beams, plates, tubing, etc. – the heavy material used for buildings, bridges, roads, signage, industrial products, etc. or perhaps vehicles and appliances.

But you may not be aware that more of the products we use every day contain recycled steel – and that manufacturers are touting their use of the material as a way to meet their environmental sustainability goals.

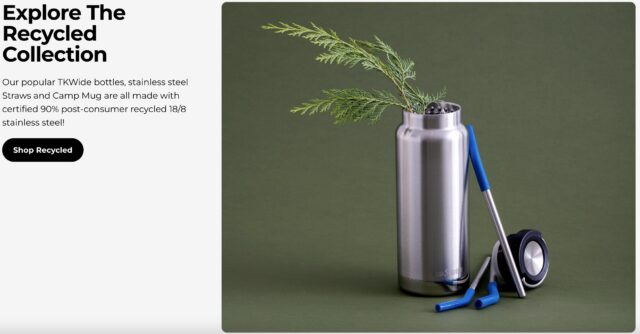

Klean Kanteen: 90% recycled steel for its 18/8 stainless steel water bottles

Kleen Kanteen Recycled Collection product page

A manufacturer of insulated water bottles, mugs, and straws, Klean Kanteen has made a commitment to use certified 90% post-consumer recycled steel throughout most of its product line. The company’s stated goal is to produce 95% of its products from recycled steel by 2023.

The Chico, CA-based family- and employee-owned company (B Corp), has listed three substantial impact reductions as a result of its efforts:

- 50% reduction in steel greenhouse gas emissions

- 30% reduction in energy demand

- 60-80% reduction in ecosystem impacts

The company states that to its knowledge, it’s “the first reusable water bottle and food solutions brand to use 90% post-consumer certified recycled steel.” The percentage of steel used is certified by Interek, a third-party quality assurance provider.

To learn more about the company and its 18/8 stainless steel hot and cold water bottles and mugs, visit: www.kleankanteen.com/pages/recycled-steel.

Liberty Tabletop: 18/10 stainless steel flatware

Photo © Sherrill Manufacturing / Liberty Tabletop

Produced by Sherrill Manufacturing in the once former Oneida Limited® manufacturing plant in Sherrill, NY, Liberty Tabletop is the only flatware made in the United States.

The company sources all of the stainless steel used from U.S. steel mills, where it was melted and processed into coils.

The company dedicates a full page on its website to educate consumers on how its steel is made:

“It is almost always manufactured by melting scrap metal, mainly similar grade stainless steel scrap. The alloying metals that make the grade of stainless steel, such as nickel and chromium, are added to the molten melt and carefully measured with sophisticated equipment to make sure the percentage is correct.”

To support the environment, which is one of the company’s values, Liberty avoids toxic chemicals, oils and lubes in its processes, and has eliminated sending dust particles into the air via filter buffering units. Energy to run the plant is sourced mainly from Niagara Falls hydro-power.

The company also works with U.S. materials vendors who produce their goods using the same environmental standards.

To learn more about the Liberty Tabletop and its 18/10 stainless flatware (and other products), visit: www.libertytabletop.com/design-value-price

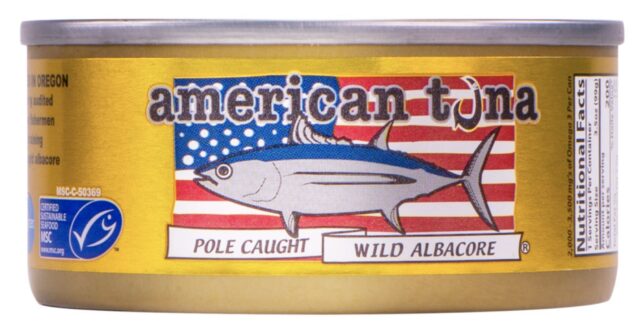

American Tuna: Pole-caught albacore tuna packed in cans made in the U.S.

Founded by American fishing families, American Tuna is the only tuna on the market that’s caught one-by-one: one fisherman, one pole, one fish at a time.

The company states all fish are tracked from exact vessel and captain that harvested the tuna to final packing via lot number, and that the product is dolphin- and turtle-safe.

As with Klean Kanteen and Liberty Tabletop, the company shares its stewardship of the environment via its Sustainability website page. As part of its efforts, the company ensures its cans are made in the United States. (To learn more about American Tuna, visit: americantuna.com)

Although the type of material to produce the cans isn’t specified, cans that hold food products are generally made of steel or aluminum, depending on the type of can.

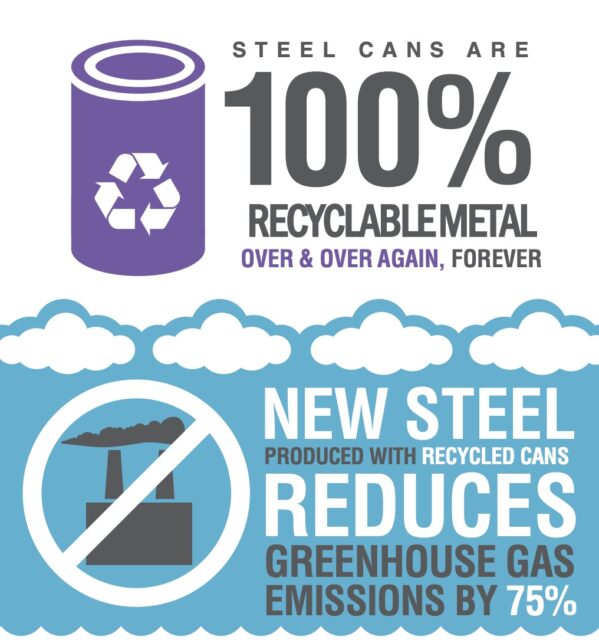

According to the Can Manufacturers Institute, steel cans are made from recycled steel, thus reducing greenhouse gas emissions by 75%. And of course, steel cans can be recycled again and again, forever! And, due to continued innovation, today’s steel cans weigh 33% less than they did 25 years ago.

The next time you open a can, you can be assured you’re supporting the environment and the metal recycling industry!

Recycled steel isn’t the only metal now being used in everyday consumer products. Part Two of this piece will cover how companies are also using recycled non-ferrous material, including aluminum and cooper.