Keep your shredder drive motor breathing clean air. Change out the air filters! Whether running an electric motor or reciprocating engines in the heat of the North American summer, you need max air flow. If you have a closed water cooled system, make sure the heat exchanger externals are clean.

Even if you have an outdoor air cooled motor, you likely have a filter within the motor enclosure. Check it monthly if not more. Motors outside of buildings are often subject to more dust and dirt than those housed in buildings.

Even if you have an outdoor air cooled motor, you likely have a filter within the motor enclosure. Check it monthly if not more. Motors outside of buildings are often subject to more dust and dirt than those housed in buildings.

If your motor is housed in a building, keep it positive pressured to cut down on dirt and dust. Many motor rooms have a negative pressure, noticeable when you first open the door. Dirty intake filters and obstructed vents are the first place to look. If that doesn’t do it you need to study the situation and find out why your exhausting more air than your drawing in. Keep in mind the answer if often add more air in, but there is a practical balance for each installation.

Your shredder’s motor protection relay is monitoring stator air temps and trying to keep the motor temp below the point the motor’s insulation suffers most. To cool the motor, that means it’s turning without load, limiting your ability to shred. A clean motor and clean filters will make for more effective cooling.

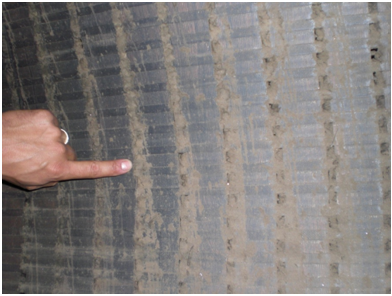

The photo below is from a dirty air cooled motor. The build up in the stator is combustible fine shredder fluff and dirt. It’s plugging up the stator section, preventing air flow through the motor.

The motor was in the shop due to a motor fire. You can guess the cause.?

Filter media can be expensive and a chore to change weekly or monthly. But it is preferable to downtime and damage.

Dirt Clogged Motor Stator