Non-ferrous metals – aluminum, copper, lead, nickel, zinc and tin – do not degrade during the recycling process and thus can be recycled an infinite number of times. Thus, nonferrous recovery and recycling has become increasingly important – both domestically and globally.

According to ISRI’s “Nonferrous Scrap Metal Market Trends” presentation, nonferrous accounted for nearly 70% of total U.S. scrap recycling earnings in 2011.

Some interesting stats (provided by the ISRI in their fact sheet):

- The US annually recycles enough copper to provide the copper content for 25,000 Statues of Liberty.

- In 2011, the US recycled enough aluminum cans to save the equivalent of 17 million barrels of gasoline – enough to fuel more than one million vehicles on the road for 12 months.

- A used aluminum can is recycled and back on the grocery shelf in as little as 60 days.

In 2012, more than 9 million metric tons of nonferrous scrap was processed in the US in from various sources – with an estimated value of $49 billion.

This scrap is then used domestically –and exported globally to over 100 countries. A $14 billion dollar industry, scrap is exported to China, Canada, Mexico, Japan and others – with China being the number one importer. According to the ISRI, from 2000 to 2011, NF scrap exports to China increased from $165M to $3.5 billion.

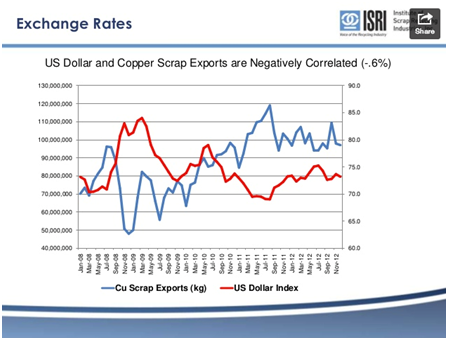

However, while NF scrap recovery in the US is booming, prices have fallen on exported NF scrap due to uncertainties including the US budget and debt ceiling challenges, exchange rate volatility (as seen in the screenshot below for copper), and global demand and supply.

The pendulum may be swinging back towards less export / more domestic consumption. USA recyclers want to see domestic consumers return to avoid transpiration, regulatory, currency, and ‘market downgrades.’ As North American manufacturing efficiencies tweak up, domestic secondary metal producers will be right behind them.

What this means for the small metals recycler

Recyclers that maintain their flexibility among markets will benefit. They need the largest group of buyers and the most markets to maximize revenue and consistent sales.

Recyclers that maintain their flexibility among markets will benefit. They need the largest group of buyers and the most markets to maximize revenue and consistent sales.

Strive for quality – be able to produce the next level of quality in short order. The next ‘Operating Green Fence’ can turn a market in short order. Be ready to meet domestic quality requirements when local markets come looking.

Innovation is rewarded – Tailoring grades to meet local markets develops your niche and often earns you a steady buyer. X-ray sorting your zorba in to cast and sheet grades (making ISRI Grade Tweak) or separating out insulated wire adds value every day.

Flexibility will help you overcome disruptions in buyers, logistics, and currency.