Weld On DFR Tooth

Your feeding device is one of the most important productivity factors in your scrap metal shredding system. The feeder is tasked with adding feed stock to the shredder at a controlled rate, both pushing it in and holding it back.

It cannot be effective without traction aides on the roller surface. Lateral bars and teeth welded to the rolls grab and move material and have sharp edges to assist. Edges are key. Rounded off lateral grab bars and teeth just don’t work as well.

Ideally, you have replacement feed rollers on the ground, ready to swap in place or have a slick one piece cast roller you can replace. Many DFR units do not. You may not have the time for a large scale DFR renewal.

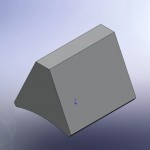

Enter the K2 Weld on Tooth.

You can renew in place replacing lateral bars and adding weld on teeth to the feed roll. Adding them over a few maintenance shifts can give you the surfaces and edges you need to grab and hold tin, bales, and loose scrap, getting your feed rate closer to new.

Fight less on the feed ramp, feed more in the shredder. Give us a call for a set.