Early 2015 is a tough time to be in the shredding business. Scrap prices continue their deep dive while the input side of the business tries to adjust to the change in value. It may be the sign of a fundamental reset in the value of scrap. Obsolete scrap volumes may lag for some time until the economics of disposal and transport become clear. If you are running a shredder on a limited schedule, can you safely defer routine maintenance?

What do we mean by routine? They are the habitual tasks that are part of best practices. They are the small things you know are important, but are tempted to defer because of limited run time or available maintenance hours. And they are normal maintenance expenditures you might be tempted to put off until better markets return. Skipping what you know works isn’t ‘adapting’ to new realities but a mentality that will cause more costly problems down the road.

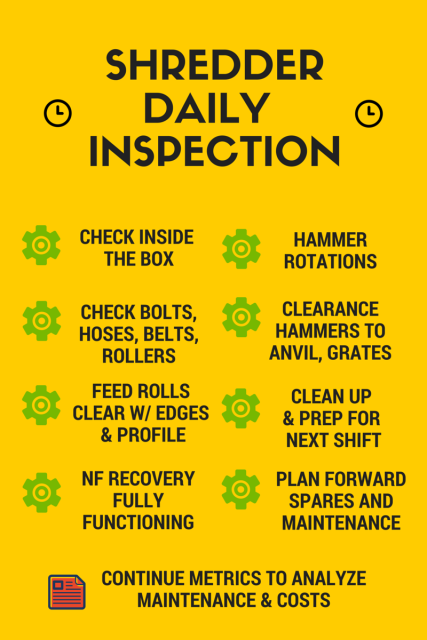

Everyone just needs to take stock of their current production requirements and adjust upon facts, not guesses. The plain truth of the matter is the shredder has to be opened and looked at after every production shift. Inspecting the box is a matter of routine, not tons. Who has not had a problem in the first part of a production shift? There may be a piece of scrap jammed in such a way it will pop off end caps or bind the rotor during start up. Inspecting after each production shift helps you plan for regular maintenance and reduces the chances of surprises.

Everything needs to be checked, despite reduced manning and run hours.

- bolts have to be tightened

- liners have to be replaced when wore down

- feed rolls have to be cleaned of scrap and maintained

- hammers need to be flipped, moved, or replaced

- check the distance between hammers and grates & anvils

- Non-ferrous recovery systems need regular checks to be sure they are fully functioning

Grates have to be checked for proper distance from the hammers to be sure you are getting the best density and non ferrous recoveries from your processing. The anvil to hammer distance keeps cutting and sizing working to ensure efficient throughput in the mill. Many things are checked on each shift that influence how well the shredder performs and keeps production costs in line with expectations.

Planning ahead on vital spares and replacement parts cannot be deferred too far into the future. If you shred, often you will need it sooner than you think. Rotors, motors, bearings can fail at the least opportune moment. Ordering ahead of time and using your labor hours in a pre-determined way helps keep overtime and costs level.

Planning ahead on vital spares and replacement parts cannot be deferred too far into the future. If you shred, often you will need it sooner than you think. Rotors, motors, bearings can fail at the least opportune moment. Ordering ahead of time and using your labor hours in a pre-determined way helps keep overtime and costs level.

In the business of shredding scrap, not everything works out as expected. Despite economizing on maintenance and repair, you know where you can defer and where you can’t. Go with the things you know work best. It will save you headaches and money in the long run.